Problems at manufacturing sites

Nowadays manufacturing sites are exposed to global competition without exception and required to manufacture products “in a smaller bulk, at a cheaper price, for a shorter time” and they have to be better in accuracy as well. You have to respond to all those matters as a fundamental solution.

This also leads to clearing the 3 problems at the same time.

This also leads to clearing the 3 problems at the same time.・Getting rid of the bottleneck

・Training workers

・Attractive work

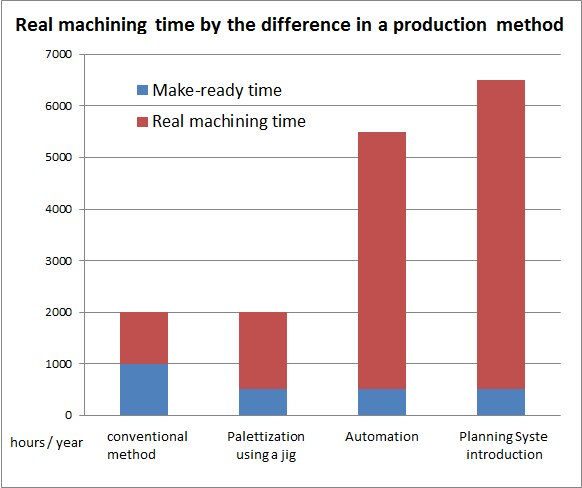

The reality is, only a half of the working time is spent for manufacturing time that leads to profit making.

Then, how should we solve the problems in order to “improve productivity”, “promote flexibility” and “achieve high precision”?

The points GF Machining Solution brings up ~ Key Factor for Success ~

The key is “Palletization” and “Automation”. In other words, productivity goes up by “reducing the idling time of machines”.